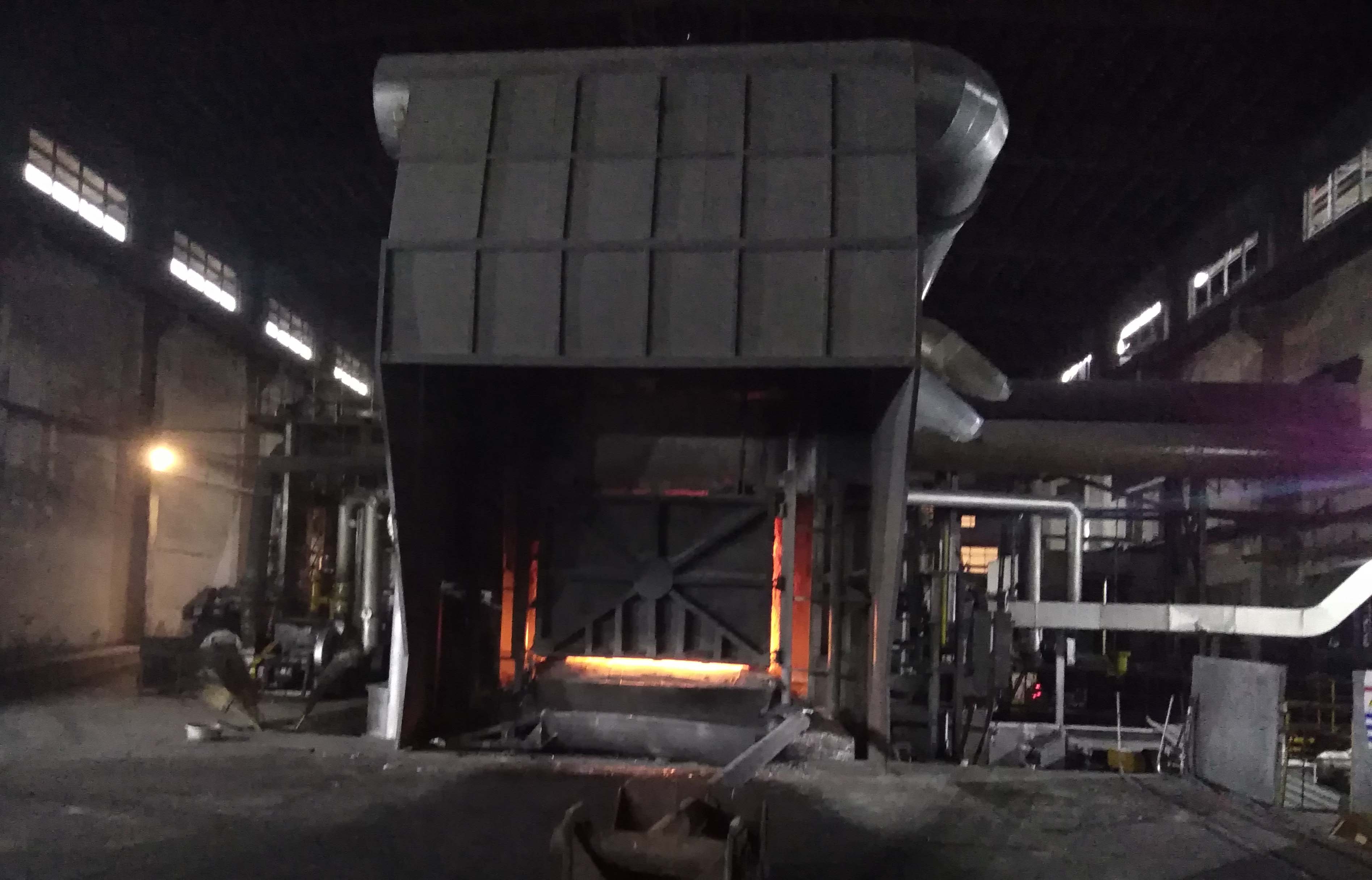

Ingot casting molds and ingot casting machine production line

Huitai melting and Ingot Casting and Stacking Facilities offers reliability, repeatability, low maintenance and high output. The fully automated melting ingot equipment can cast up to 32 tons per hour.

The ingot Casting / Stacking Facility produces smelter grade remelt ingots and foundry ingots. The equipment is suitable for both primary and secondary aluminum producers. The aluminum ingots are automatically packaged into compact stacks for easy transportation. The ingot casting machine can be operated on a continuous or semi-continuous basis depending on the furnace and metal supply capacity.

The equipment is designed for automatic operation with minimal operator input. The facility can incorporate automatic weighing, marking and strapping systems. A variety of layout configurations is available to suit your requirements, including stacks storage systems and transport methods. The cast fill Pouring System is a result of years of scientific development and collaboration with cast Cooperative Research Centre and industry. The CAST fill pouring System directs the melt into the ingot mould in a streamlined manner with minimal turbulence and splashing. Oxide levels are kept low, resulting in superior quality product with an attractive surface finish.

CAST mould is a new mould design for aluminum ingot casting which can increase productivity. The new design is based on research into the heat flow across the air gap between the ingot and mould during solidification.

Simple of operation, durability, maximisation of production and ease of maintenance are the essential design features from Huitai. Good quality ingot casting and stacking facility.

Key Benefits of Remelt Ingot Casting / Stacking Machine:

Robust equipment especially designed for cast house conditions

Proven design for optimum efficiency and high engineering standards to provide long equipment life

Proven design for optimum efficiency and high engineering standards to provide long equipment life