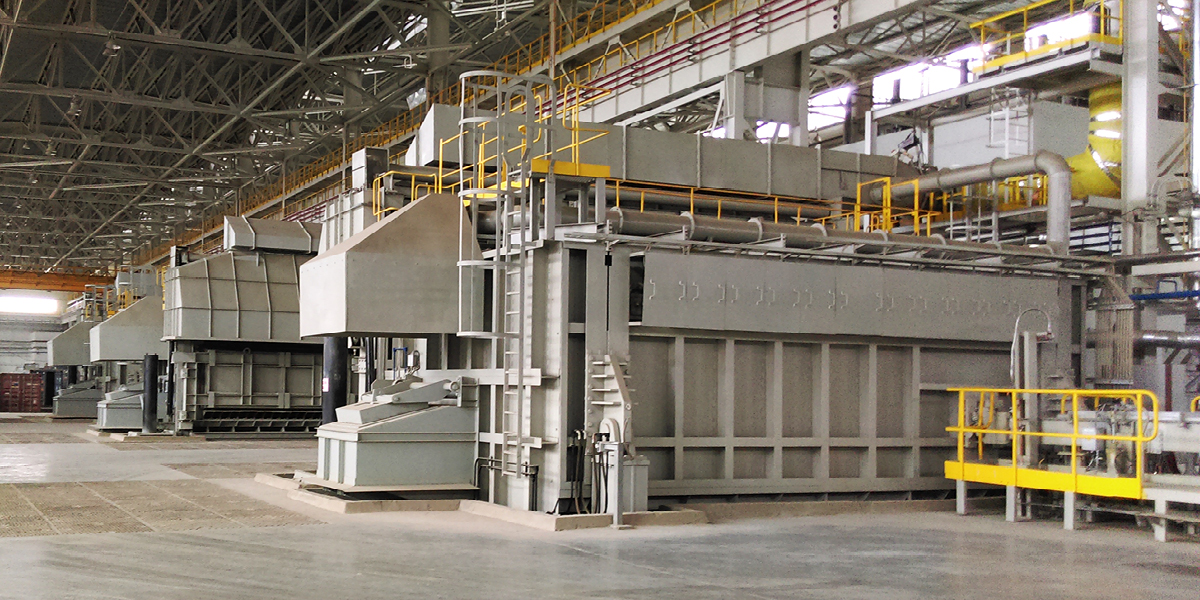

Huitai has many years experience in supplying Aluminium Holding/Casting furnaces to the Aluminium industry with many references worldwide. Huitai can offer full ‘turn key’ supply contracts as well as ‘part’ supply to suit our client's requirements. Huitai holding/casting furnaces are custom designed and constructed for arduous foundry conditions.

50 Tons capacity melting and holding furnaces

Some of our typical design features are as follows:

- Heavy duty casing construction to withstand thermal and mechanical stresses.

- Hydraulic or Electro Mechanical door lifting with synchronisation.

- Static furnace or tilting furnace designs.

- Positive pneumatic door clamping and sealing systems.

- Long lasting refractory block, cast steel or water cooled door surrounds.

- Furnace chamber exhaust ducting systems and stacks to atmosphere.

- Door fume extraction hoods.

- Automatic pressure control regulation using an actuated ‘mechanical damper’.

- Gas fired, Oil fired or electrical heat input systems.

- Electronic Fuel/Air ratio control or Thyristor control on heating elements.

- Manual or automatic metal pouring operation to suit specific casting requirements.

- Durable refractory linings in monolithic, brick or pre-cast blocks.

- Molten metal receiving wells with hot metal crucible tilting mechanisms for furnace filling.

- Specialised PC/PLC based control systems with human/machine interface giving ‘Set point’ control.

- SCADA control systems.